鑄鐵平板(鑄鐵平臺)的用途:鑄(zhu)鐵平(ping)臺(tai)(tai)可以(yi)用于檢(jian)驗機械零件(jian)平(ping)面度(du)(du),平(ping)行(xing)度(du)(du),直線度(du)(du)等形(xing)位(wei)公差的測量基(ji)準(zhun),也可用于jingmi零件(jian)的劃(hua)線和測量,實驗,鉚焊(han),焊(han)接,基(ji)礎,工(gong)作(zuo)臺(tai)(tai)等,工(gong)作(zuo)面采用刮(gua)研工(gong)藝,工(gong)作(zuo)面可以(yi)設計圓(yuan)孔,長方孔,方孔,T型槽(cao),U型槽(cao),V型槽(cao).

查看詳情

落地(di)(di)平(ping)(ping)板(ban)(ban)別名:地(di)(di)平(ping)(ping)板(ban)(ban)、地(di)(di)平(ping)(ping)臺(tai)(tai)、落地(di)(di)平(ping)(ping)臺(tai)(tai)、落地(di)(di)鏜床(chuang)工(gong)(gong)(gong)作臺(tai)(tai) 落地(di)(di)平(ping)(ping)板(ban)(ban)用(yong)途:落地(di)(di)平(ping)(ping)板(ban)(ban)是與(yu)數控落地(di)(di)鏜銑床(chuang)配套使用(yong),主要(yao)用(yong)于支(zhi)撐加(jia)工(gong)(gong)(gong)工(gong)(gong)(gong)件。主要(yao)用(yong)于機床(chuang)加(jia)工(gong)(gong)(gong)工(gong)(gong)(gong)作平(ping)(ping)面(mian)(mian)使用(yong),上面(mian)(mian)有孔和T型槽,用(yong)來固(gu)定工(gong)(gong)(gong)件,和清理(li)加(jia)工(gong)(gong)(gong)時產生(sheng)的(de)鐵(tie)屑。常見的(de)機床(chuang)工(gong)(gong)(gong)作臺(tai)(tai)如:落地(di)(di)鏜床(chuang)工(gong)(gong)(gong)作臺(tai)(tai)

查看詳情

花(hua)崗(gang)石(shi)(大(da)理石(shi))打孔工(gong)(gong)作(zuo)臺(tai) 我公(gong)司生(sheng)產(chan)的(de)花(hua)崗(gang)石(shi)(大(da)理石(shi))打孔工(gong)(gong)作(zuo)臺(tai)根據(ju)客戶的(de)具體(ti)要求和(he)圖紙加工(gong)(gong)制作(zuo),采用(yong)國(guo)內好的(de)“濟南青”石(shi)料經機械加工(gong)(gong)和(he)手工(gong)(gong)磨制成,具有度高、壽命長、耐酸(suan)堿、不易變形等優點

查看詳情

防震墊鐵減(jian)(jian)振(zhen)(zhen)橡膠(jiao)youxiao的衰(shuai)減(jian)(jian)機器自(zi)身的振(zhen)(zhen)動(dong)(dong),減(jian)(jian)少振(zhen)(zhen)動(dong)(dong)力(li)(li)外傳(chuan),阻止振(zhen)(zhen)動(dong)(dong)力(li)(li)的傳(chuan)入,保證加(jia)工尺寸度及(ji)質量(liang)。控制建筑結構諧振(zhen)(zhen)傳(chuan)播(bo)振(zhen)(zhen)動(dong)(dong)力(li)(li)和噪(zao)音。

查看詳情機(ji)床鑄造(zao)床身經(jing)過 制(zhi)模—模型涂刷-制(zhi)作(zuo)砂型-鑄造(zao)毛坯-清砂-退(tui)火(huo)處理(li)-粗(cu)加(jia)工(gong)(gong)-退(tui)火(huo)-數控機(ji)床精加(jia)工(gong)(gong)-人工(gong)(gong)刮研(yan)(yan)-處理(li)外觀(guan)-包裝、入庫(ku) 等(deng)十多道(dao)工(gong)(gong)序制(zhi)作(zuo)而(er)成。每(mei)道(dao)工(gong)(gong)序都經(jing)過研(yan)(yan)檢部門的層層把關。

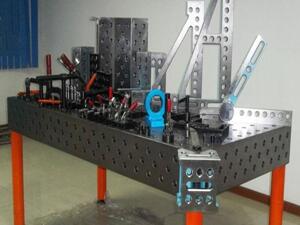

鑄鐵平臺材料為HT200-300,QT400-600,采用刮研工藝,工作面上可加工V形、T形、 U形槽、燕尾槽、圓孔、長孔等,大型鑄鐵平臺是用于工件、設備檢測、劃線、裝配、焊接、組裝、鉚焊的平面基準量具。

機床鑄件產品采用樹脂砂、消失模鑄造。材質為灰鐵HT250-300,硬度高、耐磨性能好。經過 制模—模型涂刷-制作砂型-鑄造毛坯-清砂-退火處理-粗加工-退火-數控機床加工-人工刮研-處理外觀-包裝、入庫 等十多道工序制作而成。每道工序都經過研檢部門的層層把關。

- 國產SUV精品一區二區33:機床鑄件缺陷產生的原因

發布時間:2024-11-07

- 國產SUV精品一區二區33:機床鑄件鑄造工藝和澆注準則

發布時(shi)間:2023-03-15

- 國產SUV精品一區二區33:鑄造鑄鐵工作臺時應注意的事項有哪些

發布時間:2022-08-15

- 國產SUV精品一區二區33:刮研是什么工藝?檢驗平臺為什么要刮…

發布(bu)時間:2022-07-09

- 國產SUV精品一區二區33:鑄鐵平臺的維護確保質量的方法

發(fa)布時間(jian):2022-04-04